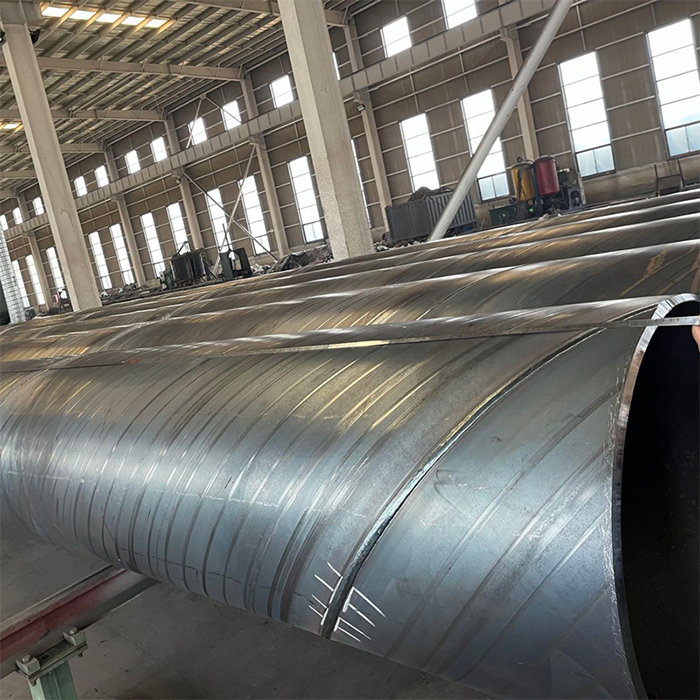

SSAW Welded Pipe

Uses: SAWH pipe are mainly used in water supply engineering, petrochemical industry, chemical industry, electric power industry, agricultural irrigation and urban construction,and is one of 20 developing key products of our country.

Size:OD: 219mm-4064mm, WT: 3.2-40mm, LENGTH: 3-70m

Grades:Q235A、 Q235B、 Q345、L245(B)、 1290 (X42)、 1320 (X46) 、 1360 X52) 、 L390(X56),L415(X60)、 L450(X65)、 L485(X70)、 L555(X80)、 1290M(X42M)、 1360M (X52M)、1390M(X56M)、IA15M(X60M)、 IA50M(X65M)、 IA85M(X70M)、L555M(X80M).

Standard:

API5L PSL1/PSL2 GrA,Gr.B,X42,X46,X52,X56,X60,X65,X70.

ASTM A53/A252/A500/ EN10219/EN10208/EN10297/JIS G3457

Coating Standard:

ANSI/AWWA C104/A21.4 American National Standard for Cement-Mortar Lining for ductile-iron Pipe and Fittings for water

DIN 30670 Polyethylene coatings of steel and fittings

| Specification: | Ranfe | |||||

| Out Diameter | 219mm-4064mm | |||||

| Wall Thickness | 3.2mm-40mm | |||||

| Length | 30m-70m | |||||

| ASTM A53 | Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless | ||||||||||

| API 5L | Specification for Line Pipe(Two levels PSL 1 and PSL 2 of seamless and welded steel pipes for use in pipeline transportation systems in the petroleum and natural gas industries.) | ||||||||||

| A252 | Standard Specification for Welded and Seamless Steel Pipe piles | ||||||||||

| A500 | Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes | ||||||||||

| EN10219-1 | Cold formed welded structural hollow sections of non-alloy and fine Grain steels - part1: Technical delivert conditions | ||||||||||

| EN10219-2 | Cold formed welded structural hollow sections of non-alloy and fine grain steels - part2: tolerances dimmsions and sectional properties | ||||||||||

Chemical Analysis and Mechanical Properties

| Standard | Grade | Chemical Composition(max)% | Mechanical Properties(min) | |||||

| C | Si | Mn | P | S | Tensile Strength(Mpa) | Yield Strength(Mpa) | ||

| API 5L PSL1 | A | 0.22 | - | 0.9 | 0.03 | 0.03 | 335 | 335 |

| B | 0.26 | - | 1.2 | 0.03 | 0.03 | 415 | 415 | |

| X42 | 0.26 | - | 1.3 | 0.03 | 0.03 | 415 | 415 | |

| X46 | 0.26 | - | 1.4 | 0.03 | 0.03 | 435 | 435 | |

| X52 | 0.26 | - | 1.4 | 0.03 | 0.03 | 460 | 460 | |

| X56 | 0.26 | - | 1.4 | 0.03 | 0.03 | 490 | 490 | |

| X60 | 0.26 | - | 1.4 | 0.03 | 0.03 | 520 | 520 | |

| X65 | 0.26 | - | 1.45 | 0.03 | 0.03 | 535 | 535 | |

| X70 | 0.26 | - | 1.65 | 0.03 | 0.03 | 570 | 570 | |

| API 5L PSL2 | B | 0.22 | 0.45 | 1.2 | 0.025 | 0.15 | 415 | 415 |

| X42 | 0.22 | 0.45 | 1.3 | 0.025 | 0.15 | 415 | 415 | |

| X46 | 0.22 | 0.45 | 1.4 | 0.025 | 0.15 | 435 | 435 | |

| X52 | 0.22 | 0.45 | 1.4 | 0.025 | 0.15 | 460 | 460 | |

| X56 | 0.22 | 0.45 | 1.4 | 0.025 | 0.15 | 490 | 490 | |

| X60 | 0.12 | 0.45 | 1.6 | 0.025 | 0.15 | 520 | 520 | |

| X65 | 0.12 | 0.45 | 1.6 | 0.025 | 0.15 | 535 | 535 | |

| X70 | 0.12 | 0.45 | 1.7 | 0.025 | 0.15 | 570 | 570 | |

| X80 | 0.12 | 0.45 | 1.85 | 0.025 | 0.15 | 625 | 625 | |

| ASTM A53 | A | 0.25 | 0.10 | 0.95 | 0.050 | 0.145 | 330 | 330 |

| B | 0.30 | 0.10 | 1.2 | 0.050 | 0.145 | 415 | 415 | |

| ASTM A252 | 1 | - | - | - | 0.050 | - | 345 | 345 |

| 2 | - | - | - | 0.050 | - | 414 | 414 | |

| 3 | - | - | - | 0.050 | - | 455 | 455 | |

| EN10217-1 | P195TR1 | 0.13 | 0.35 | 0.7 | 0.025 | 0.02 | 320 | 320 |

| P195TR2 | 0.13 | 0.35 | 0.7 | 0.025 | 0.02 | 320 | 320 | |

| P235TR1 | 0.16 | 0.35 | 1.2 | 0.025 | 0.02 | 360 | 360 | |

| P235TR2 | 0.16 | 0.35 | 1.2 | 0.025 | 0.02 | 360 | 360 | |

| P265TR1 | 0.20 | 0.40 | 1.4 | 0.025 | 0.02 | 410 | 410 | |

| P265TR2 | 0.20 | 0.40 | 1.4 | 0.025 | 0.02 | 410 | 410 | |

| EN10217-2 | P195GH | 0.13 | 0.35 | 0.7 | 0.025 | 0.02 | 320 | 320 |

| P235GH | 0.16 | 0.35 | 1.2 | 0.025 | 0.02 | 360 | 360 | |

| P265GH | 0.20 | 0.40 | 1.4 | 0.025 | 0.02 | 410 | 410 | |

| EN10217-5 | P235GH | 0.16 | 0.35 | 1.2 | 0.025 | 0.02 | 360 | 360 |

| P265GH | 0.20 | 0.40 | 1.4 | 0.025 | 0.02 | 410 | 410 | |

| EN10219-1 | S235JRH | 0.17 | - | 1.4 | 0.040 | 0.040 | 360 | 360 |

| S275JOH | 0.20 | - | 1.5 | 0.035 | 0.035 | 410 | 410 | |

| S275J2H | 0.20 | - | 1.5 | 0.030 | 0.030 | 410 | 410 | |

| S355JOH | 0.22 | 0.55 | 1.6 | 0.035 | 0.035 | 470 | 470 | |

| S355J2H | 0.22 | 0.55 | 1.6 | 0.030 | 0.030 | 470 | 470 | |

| S355K2H | 0.22 | 0.55 | 1.6 | 0.030 | 0.030 | 470 | 470 | |