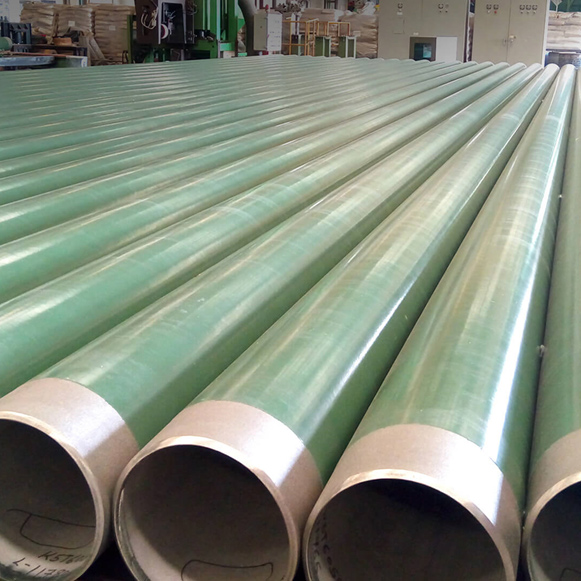

Epoxy Coating Pipe

Application: Used for natural gas, petroleum, water & sewage, and pipe systems

Standard:AWWA C210

Pipe diameter: Φ168-1422mm (6-56 inch); Coating type: FBE, 2FBE, 2LPE, 3LPE/PP

Various steel pipe external coating projects are currently implemented by Xunhong steel co.,ltd including single-layer/double-layer FEB, 2PE, 3PE, 3PP, Cement mortar covering and other anti-corrosion coatings with the performed standards such as DIN30670,DIN30671, DIN30678, CAN/CSA-7245.21-M92,SY/T4013-2002, SY/T0315-97 etc.

The epoxy pipe coating system is a non-invasive process which uses air to move the epoxy through the pipe. completely coating the walls as it passes through.

As the application is carried out using air, this means we can coat pipes as small as 15mm and negotiate multiple bends and tees, further reducing the need to break into the building at these points

The epoxy coating creates a barrier between the walls of the host pipe and the contents eliminating internal corrosion and helping the prevention of the growth of legionella and other micro- organisms. lt also prevents leaching from lead pipes or contaminated soil.

The pipes could be carrying anything from potable water, steam, chemicals, fuels, sewage, gases, we have it covered at PLS

| Coating Type | Coating Layer | Coating Thickness | |||||

| 3PE Three layers Polyethylene | Inside layer:epoxy(Green) | 2.0-4.5mm | |||||

| Middle layer:adhensive(White) | |||||||

| Outside layer:polyethylene(Black) | |||||||

| 2PE Two layers polyethylene | Inside layer:adhensive | 2.0-4.5mm | |||||

| Outside layer:polythene | |||||||

| FBE | Epoxy | 200-400um | |||||

| 环氧粉末 | |||||||

| 2FBE Two layers epoxy | Inside layer:epoxy(Green) | 400-800um | |||||

| Outer layer:intensity epoxy(sage green) | |||||||

| 3PP Three layers polyethylene | Inside layer:epoxy(Green) | 2.5-3mm | |||||

| Middle layer:adhensive(White) | |||||||

| Outside layer:polypropylene(White) | |||||||

| Cement coated | 60-110mm | ||||||

| Standard | API 5L | ||||||

| Grade | PSL-1 | API 5L-Gr.B/X42/X46/X52/X60/X70 etc. | |||||

| (material) | PSL-2 | ISO3183-L245/L290/L320/L360/L415/L485 etc | |||||

| Outside Diameter Ranges | PSL-1 | 0.405-80(in) or 10.3mm-2032mm | |||||

| PSL-2 | 4 1/2-80(in) or 114.3mm-2032mm | ||||||

| Wall Thickness ranges | SCH10~SCH160 0r STD,XS,XXS Or 1.73mm~59.54mm | ||||||

| Length | For 20Ft Container | 4.8m-5.8m | |||||

| Negotiable | For 40Ft Container | 4.8m-12m | |||||

| Most common choice | 6m, 12m | ||||||

| Type | Welded | ERW.,LSAW/SSAW | |||||

| Seamless | Cold Drawn,Hot Finished,Hot Expanded | ||||||

| Cap(negotiable) | Pipe size should under DN600 | ||||||

| Pipe end | Plain end | All sizes | |||||

| Bevel end | Pipe size above DN50, and the thickness should greater than 3.2mm | ||||||

外涂层External Coating

| 涂层类别 Coating type | 涂层标准Coating Standard | |||||||

| 3LPE/3LPP | DIN30670-1991,CAN/CSA Z245,21-2010,ISO21809-1-2009 SY/T 0413-2002,GB/T23257-2009 | |||||||

| 2LPE/2LPP | SY/T 0315-2002,GB/T23257-2009,ISO21809-1-2009 | |||||||

| FBE(Fusion-bond epoxy) | SY/T 0315-2005,AWWA C213-2001,CAN/CSAZ245.20-2010,IS0218909-2-2007,API RP5L9-2001 | |||||||

| Bitumen coating Enamel & Tape hot-applied | BS534-1990,AWWA203-2002,AWWA214-2000 | |||||||

| Liquid epoxy coating | AWWWA C210-2007 | |||||||

| Polyurethane insulated coating | SY/T0415-1996,CJ/T114-2000.EN253-1994 | |||||||

| 内涂层Internal Coating | ||||||

| Liquid Epoxy Coating | AWWAC210-2007 | |||||

| FBE | AWWAC213-2001 | |||||

| Cement Mortar Lining | BS534-1990,AWWA C205-2001 | |||||

| Bitumen Coating | BS534-1990 | |||||