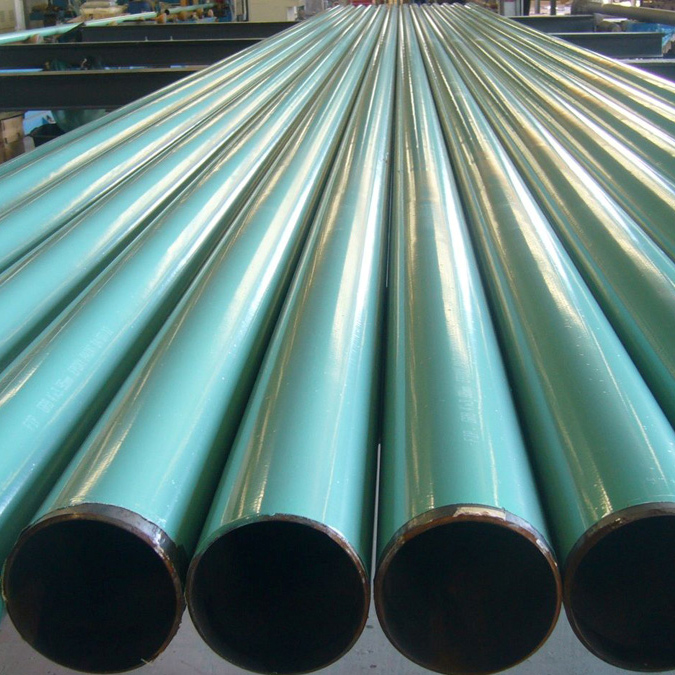

FBE Coating Pipe

Application: Used for natural gas, petroleum, water & sewage, and pipe systems

Pipe diameter: Φ168-1422mm (6-56 inch); Coating type: FBE, 2FBE, 2LPE, 3LPE/PPE

End:Plain End/Bevelled End, Burr Removed

Description:

FBE pipe is coated with Epoxy Coatings, it could be used for internal and exernal coating, and mostly used pipe internal coating. Specified as Fusion Bonded Epoxy pipe.

FBE coating pipe is Fusion Bonded Epoxy coating steel pipe.lt could be applied for external or internal coating, with heat resin for pipe. With coated a form of dry powder at thickness 400-600 microns on to the heated surface of pipe. Once the FBE coated on the pipe surface, the FBE film provides an extremely hard surface with great adhesion to the pipe surface. The FBE layer in a even form and have good resistance to the chemical reaction.

Application:Widely used in pipeline systems for the transmission of oil, gas, water and other fluids. They have highly resistance to corrosive from chemicals, moisture, harmful environment etc

Feature:

FBE can be applied at service temperatures of up to 110℃, the typical thickness is 350 to 450 micrometres. For increased resitance to mechanical loads, additional layers of special epoxy can be applied. This is known as dual FBE coating or abrasion-resistant overlay (ARO)

FBE DUAL LAYER: 1st layer -- Corrosion protection epoxy powder spray- applied with electrostatic guns in typical thickness of 250 - 275 um.

FBE DUAL LAYER: 2nd layer - Mechanical protection epoxy powder spray-applied with electrostatic guns in typical thicknessof 375 - 625 um.

FBE MONO LAYER: Epoxy powder spray-applied with electrostatic guns in typical thickness of 350 - 450 um.

Bare pipe:

Stainless steel pipe

ASTM A312,ASTM A269 stainless pipe

Carbon steel pipe

API 5L line pipe from Grade B to Grade 80

ASTM A53 pipe (Hot dipped galvanized steel pipe)

ASTM A106 pipe

ASTM A252 pipe

ASTM A134 and A135

ASTM A333

Alloy steel pipe

ASTM A335

Nickel Alloy pipes

CRA clad or lined pipe

Specification:

| M kg/m | Layer thickness in mm | ||||||||

| Class A1 | Class A2 | Class A3 | Class B1 | Class B2 | Class B3 | Class C1 | Class C2 | Class C3 | |

| M≤15 | 1.8 | 2.1 | 2.6 | 1.3 | 1.8 | 2.3 | 1.3 | 1.7 | 2.1 |

| 15<M≤50 | 2 | 2.4 | 3 | 1.5 | 2.1 | 2.7 | 1.5 | 1.9 | 2.4 |

| 50<M≤130 | 2.4 | 2.8 | 3.5 | 1.8 | 2.5 | 3.1 | 1.8 | 2.3 | 2.8 |

| 130<M≤300 | 2.6 | 3.2 | 3.9 | 2.2 | 2.8 | 3.5 | 2.2 | 2.5 | 3.2 |

| 300<M | 3.2 | 3.8 | 4.7 | 2.5 | 3.3 | 4.2 | 2.5 | 3.0 | 3.8 |

Please note: The total required thickness may be reduced for SAW pipes by a maximum of 10% on joint seam.

Class 1 and 2 for medium and light applications (sandy soil).

Class 3 - application in extreme conditions (rocky soil) or underwater.

Minimum thickness of finished coating

| Pipe Sizes (Specified OD) | Minimum Coating Thickness Chart (mm) | ||||||||

| ≤10 3/4"(273.1mm) | 2.5 | ||||||||

| > 12 3 /4" ( 323.9 mm) to ≤18" (457 mm) | 2.8 | ||||||||

| > 20" (508.0 mm) to ≤30" (762 mm) | 3 | ||||||||

| > 32"(813.0 mm) | 3.3 |

THICKNESS OF FBE COATING ON STEEL PIPES

| DN(mm) | Epoxy Powder(㎛) | Adhesive Layer(㎛) | Min.Thickness on the Coating(mm) | ||||||

| Common Level(G) | Strength Level(S) | ||||||||

| DN≤100 | ≥120 | ≥170 | 1.8 | 2.5 | |||||

| 100<DN≤250 | 2 | 2.7 | |||||||

| 250<DN<500 | 2.2 | 2.9 | |||||||

| 500≤DN<800 | 2.5 | 3.2 | |||||||

| DN≥800 | 3 | 3.7 | |||||||

DIN 30670-2012 Polyethylene Coatings on Steel Pipes and Fittings

ISO 21809-1:2011 Petroleum and natural gas industries--External coatings for buried or submerged pipelines used in pipeline transportation systems -- Part 1: Polyolefin coatings (3-layer PE and 3-layer PP)

CAN CSA Z245.21 External Polyethylene Coating for Pipe

NFA 49-710 External Three-Layer Polyethylene Based Coating, Application by Extrusion

SHELL DEP 31.40.30.31-CSPC External Polyethylene and Polypropylene Coating for Line Pipe