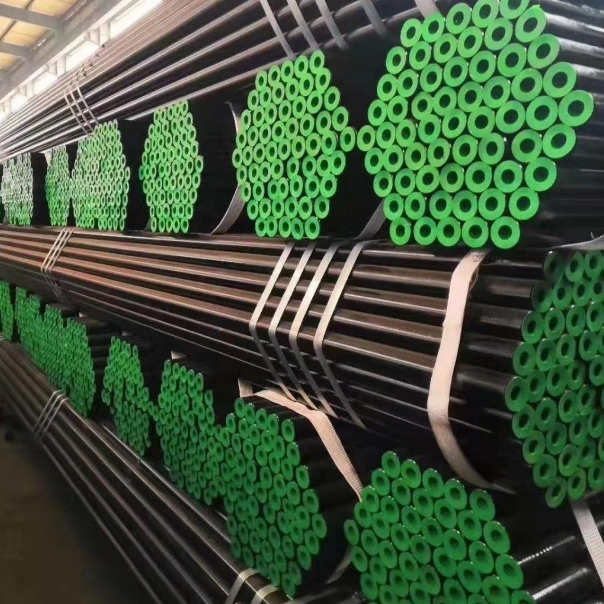

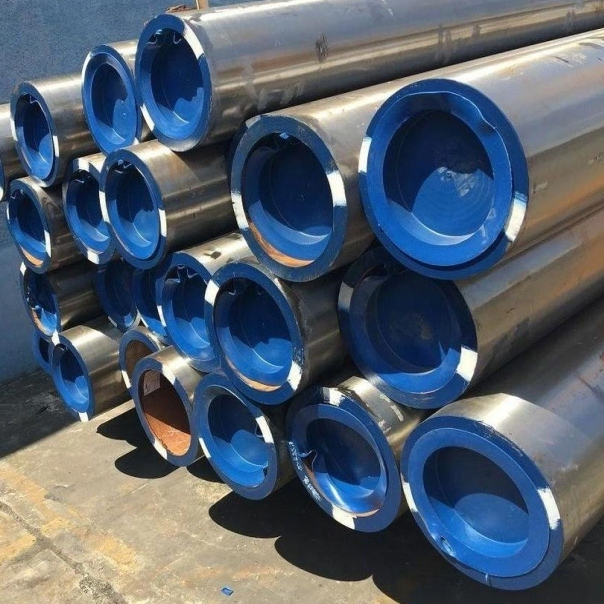

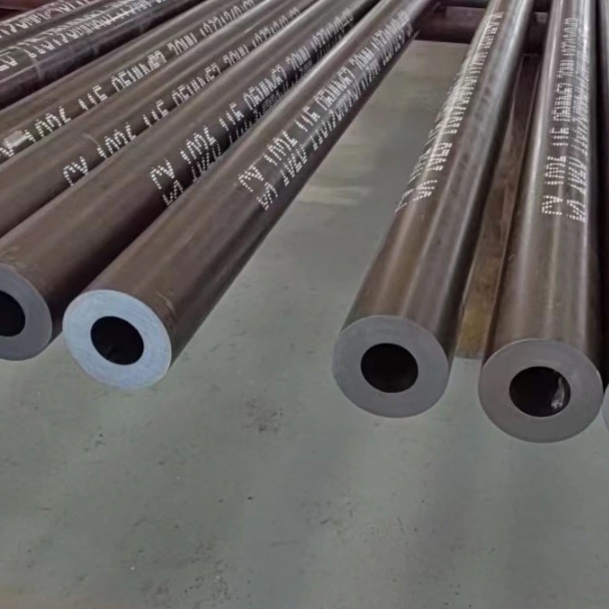

ASTM A519 Steel Pipe

Size range(mm):Out diameter:10-324mm;Wall Thickness:1-30mm;Length:14000mm max

Grade:ASTM A519 1020;1025;1026;1035;1045;4130;4140

Application:

For mechanical engineering

For mechanical and pressure use,and also for transporting steam,water,gas and etc

Xunhong steel Co.,ltd the leading manufacturers and suppliers of astm a519 steel pipe

This specification covers for several grades of carbon and alloy steel mechanical tubing, either hot-finished or cold-finished. The steel used in the mechanicaltubing may be cast in ingots or may be strand cast,When steel of different grades is sequentially strand cast, identificaton of the resultant transition material is required. The seamless tubing is a tubular product made without a welded seam, It is usually manuafactured by hot working steel,and If necessary, By subsquently cold finishing the hot-worked tubular product to produce the desired shape, dimensions and Properties, the tubes shall be furnished in the following shapes: round, square,rectangular and special Sections. Heat analysis shall be made to determine the percentages of the elements specified,if secondary melting processes are used,the heat analysis shall be obtained from one remelted ingot or the product of one remelted ingot of each primary melt, the tubing shall be coated with a film of oil before shaping to retard rust when specified.

| OD(mm) | Wall Thickness Unit(mm) | |||||||||||||

| 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 6 | 6.5-7 | 7.5-8 | 8.5-9 | 9.5-10 | 11 | 12 | |

| Φ25-Φ28 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ32 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ34-Φ36 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ38 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ40 | ● | ● | ● | ● | ● | |||||||||

| Φ42 | ● | ● | ● | ● | ● | |||||||||

| Φ45 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ48-Φ60 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ63.5 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ68-Φ73 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ76 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ80 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ83 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ89 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ95 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ102 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ108 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ114 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ121 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ127 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ133 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ140 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ146 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ152 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ159 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ168 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Pipe Type | Pipe Sizes | Tolerances | |||||

| Cold drawn | OD | ≤48.3mm | ±0.40mm | ||||

| WT | ≥60.3mm | ±1% mm | |||||

Chemical Composition(%)

| Grade | C | Mn | P≤ | S≤ | Si | Cr | Mo |

| 1008 | ≤0.1 | 0.30-0.50 | 0.04 | 0.05 | - | - | - |

| 1010 | 0.08-0.13 | 0.30-0.60 | 0.04 | 0.05 | - | - | - |

| 1018 | 0.15-0.20 | 0.60-0.90 | 0.04 | 0.05 | - | - | - |

| 1020 | 0.18-0.23 | 0.30-0.60 | 0.04 | 0.05 | - | - | - |

| 1025 | 0.22-0.28 | 0.30-0.60 | 0.04 | 0.05 | - | - | - |

| 1026 | 0.22-0.28 | 0.60-0.90 | 0.04 | 0.05 | - | - | - |

| 4130 | 0.28-0.33 | 0.40-0.60 | 0.04 | 0.05 | 0.15-0.35 | 0.80-1.10 | 0.15-0.25 |

| 4140 | 0.38-0.43 | 0.75-1.00 | 0.04 | 0.05 | 0.15-0.35 | 0.80-1.10 | 0.15-0.25 |

Mechanical properties

| Grade | Condition | Mpa Tensile Point | Yield Point | Elongation | |||

| 1020 | CW | ≥414 | ≥483 | ≥5% | |||

| SR | ≥345 | ≥448 | ≥10% | ||||

| A | ≥193 | ≥331 | ≥30% | ||||

| N | ≥234 | ≥379 | ≥22% | ||||

| 1025 | CW | ≥448 | ≥517 | ≥5% | |||

| SR | ≥379 | ≥483 | ≥8% | ||||

| A | ≥207 | ≥365 | ≥25% | ||||

| N | ≥348 | ≥379 | ≥22% | ||||

| 4130 | SR | ≥586 | ≥724 | ≥10% | |||

| A | ≥379 | ≥517 | ≥30% | ||||

| N | ≥414 | ≥621 | ≥20% | ||||

| 4140 | SR | ≥689 | ≥855 | ≥10% | |||

| A | ≥414 | ≥552 | ≥25% | ||||

| N | ≥621 | ≥855 | ≥20% | ||||